- News

A new generation of linear axes

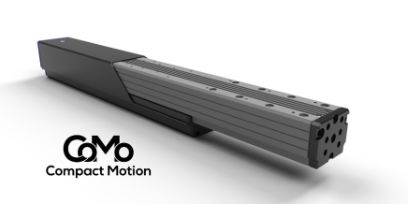

01.09.2025 How can industrial drive systems be made more compact, smarter and more efficient? It was with this question in mind that the start-up Compact Motion and the robotics laboratory at the Institute for Human Centred Engineering at BFH launched a joint research project. Today, one thing is certain: the results achieved mark the beginning of a new era for linear axes.

Key points at a glance

- As part of an Innosuisse project, the start-up Compact Motion and researchers from the robotics laboratory (HuCE-roboticsLab) have developed a new generation of linear axes for industrial automation.

- The Rhino-100 linear motor integrates the control system directly into the motors.

- This compact, high-performance system saves on costs and assembly effort.

With the aim of making handling systems for industrial automation more compact, smarter and more efficient, start-up Compact Motion has developed the Rhino-100 linear axis prototype. It quickly became apparent that the potential was enormous, but that decisive technical hurdles had to be overcome before series production could begin.

HuCE– Robotics Laboratory

Our know-how at the Robotics Laboratory (HuCE-roboticsLab) ranges from industrial to mobile robotics with research focus on collaborative robotics.

Institute for Human Centered Engineering – Robotics Laboratory

From idea to research project

In collaboration with the robotics laboratory at the Institute for Human Centred Engineering (HuCE-roboticsLab), Compact Motion therefore launched a research project. One of the main challenges was the thermal behaviour of the prototype. There was also no reliable way to measure the drive characteristics. In addition, there was the question of how a linear motor for vertical applications could maintain its position when switched off without relying on external counterweights – a well-known shortcoming of conventional linear motors. Finally, a solution had to be found for the complex wiring of multiple axes.

Impressive results

The collaboration yielded impressive results. The BFH developed a test bench that can be used to systematically record all drive characteristics. Using state-of-the-art simulation methods, an integrated counterbalance was designed, which has since emerged as a unique selling point. Modelling and targeted optimisations have significantly improved thermal behaviour, meaning that the axis can now be used reliably in continuous operation. In addition, innovative concepts for communication and energy supply have been developed.

The basis for the next generation

With these advances, Compact Motion has not only mastered crucial technological challenges, but also laid the foundation for a new generation of drive systems. The further development of motor technology makes it possible to offer various axis models in a modular format and prepare for series production.

The result: a compact, powerful and intelligent drive that has the potential to bring about lasting change in industrial automation.